Fuel Cell APU for Trucks

Technical background of the system

Diesel driven fuel cell system at the truck as packaging-study. Illustration: Eberspächer

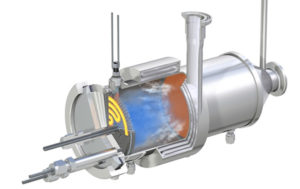

The fuel cell-APU, which is developed within the project “ENSA” by the consortium of the companies Eberspächer Climate Control Systems, ElringKlinger and Behr, contains all technical components that are necessary for mobile power generation. A reformer, which has been developed with the support of OWI, transforms diesel fuel out of the vehicle´s tank and out of ambient air into a synthesis gas by means of catalytic partial oxidation. This synthesis gas, which mainly consists of hydrogen and carbon monoxide, reacts in the SOFC-fuel cell with the fed atmospheric oxygen. The reaction takes place within a controllable, electrochemical process that generates electrical power.

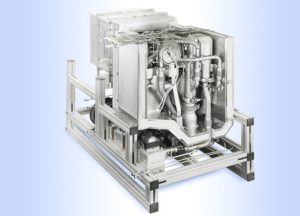

The working prototype as an ENSA II demonstrator. Photo: Eberspächer

To heat up the fuel cell to the required temperature of about 800 °C, a start burner with a heat exchanger, which is driven by diesel fuel, is integrated. As the fuel cell is not able to transform burner gas into electrical power completely, the flammable exhaust gas parts are led into an off gas burner.

The reformer of the fuel cell system transforms Diesel into a hydrogen-rich gas. Illustration: Eberspächer

The heat, which results from off gas combustion, is used for the preheating of the air needed in the fuel cell. The steam of the not transcribed fuel cell exhaust gas is led into the reformer again for cooling and stabilization – comparable to the exhaust gas recirculation of combustion engines.

SOFC-stack module of the company ElringKlinger. Foto: ElringKlinger