Structural Mechanics

At OWI, the focus is on the application of numerical structural analysis (CSM – Computational Structural Mechanics) for components with high thermal load. The thermal load on the material depends on the thermal boundary conditions of the fluid flow, such as the heat release due to chemical reactions. In case of technical components, the short-term mechanical load which is caused by heating and cooling processes is particularly important.

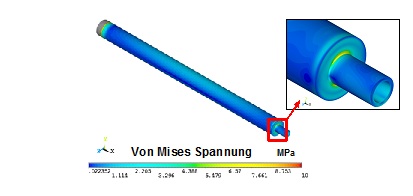

CSM simulation. Photo: OWI

High-temperature gradients will lead to high tensions, especially in the case of thin-walled components, which can cause deformations and damages. In micro process engineering the magnitude of thermally caused deformations are in the range of characteristic component dimensions (e.g. channel width). One application area is the field of the micro fuel cells where the tightness of fuel cells can be guaranteed, e.g. those that have been developed in the publicly funded project MIMEMIZ at OWI. The cell is constructed from various individual micro channels. The thermal deformation of components under operating conditions was determined by means of a stress analysis (see above).

CSM simulation. Photo: OWI

In high-temperature technology, damage mechanisms of components occur because of the extreme thermal material load. In long-term observation creep process and high-temperature corrosion decide the load condition and are thus important for the durability analysis. A typical example is the deflection of radiant tubes in industrial furnaces. Similar problems were investigated with numerical methods within the scope of the project HT-LifePLUS et al., which is funded by the Federal Ministry of Economics and Technology.