Control Development

Controlling Systems Efficiently and Safely

OWI is involved in projects which aim at the development of total systems for power generation, such as fuel cell systems, heating systems or fuel processors. At OWI itself, there are various total systems for this purpose. These highly complex systems and test benches as well as their various technical components have to be controlled by special hard- and software so that safe, smooth and automatic processes can be guaranteed. Frequently, interdependencies between the individual components occur – accordingly encompassing is the need for control of these systems.

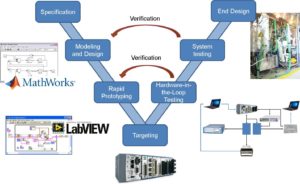

V-Model is an essential part of the control and regulation technology at OWI. Illustration: OWI

The group control development at OWI has gained a comprehensive know-how in semi- and fully automatic systems. This group designs, develops and tests system controls, takes them into service and is responsible for their optimisation and maintenance. For this purpose software, such as LabVIEW, Step7 or Matlab/Simulink, is used.

In the development phase controlers are developed virtually. The aim is to save time and costs as well as to design reliable systems before their commissioning. For this purpose, the group develops dynamic system models. The experts use the system models within a Hardware-in-the-Loop environment.

The control program is translated into a software code. Then, it is run together with the simulation model on a development computer. Thus, performance tests are already possible in an early development phase without technical components. If the tests of the control software proceed successfully, the real control hardware, such as Compact FieldPoint, CompactRio or MicroAutoBox, will be involved in a next step. Hardware and software are combined in a Hardware-in-the-Loop-method with system components which are initially depicted only virtually by simulation. Possible malfunctions which could be a risk for humans and machines can be already fixed before commissioning.