Smart CHP

Smart and flexible Heat & Power from Biomass derived liquids for small-scale CHP application

Short description

Small scale biomass-based Combined Heat and Power (CHP) has the potential to contribute significantly in solving the challenges Europe faces in making its energy system smart, clean, flexible, secure, cost competitive and efficient. High efficiencies are achieved by combining heat and power generation, and even cooling can be integrated in such a scheme. Furthermore, CHP can play an important role in securing electricity supply by balancing a Renewable Energy Sources (RES) based grid (“dispatchable powerâ€) to compensate for fluctuating wind and solar electricity.

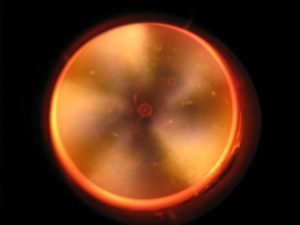

Flame pattern of a combustion of pyrolysis oil (FPBO). Photo: OWI

For small-scale biomass CHP systems, a standardized fuel, that can be produced with an optimized process, thereby creating a cost competitive value chain, is highly preferred. Moreover, to achieve high resource efficiencies at all times a highly flexible ratio between heat and power generation is desired. A smart, demand driven unit should be capable of dealing with the fluctuating energy demand and/or varying availability of wind/solar power.

Objectives of the project

The overall objective of SmartCHP is the realization of a cost-effective and flexible energy system by using a liquid intermediate energy carrier in an efficient diesel-engine based CHP. More specifically, it concerns the development of a smart and flexible, small-scale CHP unit (100 – 1,000 kWe) fuelled with fast pyrolysis bio-oil (FPBO) originating from different types of lignocellulosic biomasses and/or residues. Fast pyrolysis is a process to convert a variety of biomass resources into a uniform liquid fuel called FPBO. The SmartCHP system combines a FPBO fuelled engine and flue gas boiler to produce electricity and heat at a high efficiency over the whole load range. Furthermore, SmartCHP enables higher levels of renewables in the electricity system by providing a flexible, responsive and intelligent solution. To achieve the overall project objective a number of specific technical and non-technical objectives have been defined:

- Experimental testing of FPBO in compression-ignition engines for combined heat and power production including start and stop procedures;

- Development of a flue gas boiler enabling the feeding of extra FPBO for additional heat production using the flue-gas from the engine;

- Further development of the FPBO fuel injection system for both the engine and boiler;

- Fundamental research into the atomization and combustion of FPBO to support the development of the boiler and engine application;

- Development of the catalytic flue gas treatment system for reducing CO, hydrocarbons (HC), NOX, and particle matter (PM) to comply with (European) emission regulation;

- Development of a predictive, real-time dynamic system model to enable smart control of the SmartCHP unit and to balance variable intermittent RES;

- Integration of the engine, boiler and flue gas treatment system in to a single unit and perform overall system testing and evaluation for a wide range of heat and power output ratio´s mimicking a real environment;

- Provide input for the upgrading of the CEN Technical Report to a European Standard;

- Assessment of market opportunities by performing techno-economic, legislative, socio-economic and environmental studies illustrated by a number of case studies.

Working tasks OWI

- Boiler development and integration of the flue-gas treatment

The aim of this task is to demonstrate that FPBO can be used as an alternative fuel for the boiler in a CHP system. The development will start with an existing unit of approx. 100 kWth, which is available for combustion of heating oil. The boiler will be adapted to enable FPBO and should work on highly variable conditions of mass flows (thermal power levels), temperatures and composition of the flue gas coming from the engine. Investigation of possible strategies to ensure reliable start/stop operation of the FPBO fired boiler under various conditions based on the defined operating conditions and requirements. - At OWI several materials will be tested under FPBO (synthetic) flue conditions to assess the impact of the trace species on the used catalysts materials in the flue-gas treatment system at given high temperatures.

- Investigation of Health & Safety (HSE) and REACH aspects of FPBO application and logistics

Project Partners

- OWI Science for Fuels gGmbH

- Abato Motoren

- Exergia Energy and Environmental Consultants

- Capax Environmental Services

- Greenovate! Europe

- Technical University of Eindhoven

- Tehag Germany

- Denmark Technical University

- Dowel Management

- BTG Biomass Technology Group (Projektkoordination)

Project funding

The SmartCHP project has received funding of €4 million from the European Union´s Horizon 2020 research and innovation programme under grant agreement no. 815259.

The SmartCHP project has received funding of €4 million from the European Union´s Horizon 2020 research and innovation programme under grant agreement no. 815259.

Project duration

6/ 2019 until 5/ 2023

Contact

Dipl.-Ing. Melanie Grote

Phone: 02407/ 9518-123

e-mail: M.Grote@owi-aachen.de

Dr.-Ing. Sangeetha Ramaswamy

Phone: 02407/ 9518-143

e-mail: S.Ramaswamy@owi-aachen.de